The company stated that choosing wide-format ink is a “crucial decision”.

On LinkedIn, the company’s Sunny Hope, working in Wide-Format Ink Marketing, wrote a piece entitled How to choose ink for wide-format digital printing, in which she notes that “it is important not to forget about the unsung heroes of the print production process, such as ink, for ensuring the highest quality products. While print machinery may be an important consideration for the production process, so are the consumables used during the process”.

She added that choosing the ink and pigments “has always been a crucial decision, one that is very much related first of all to the selected printing method and secondly to the preferred substrate. Can this or that digital printing device use an ink that you’re familiar with from analogue screen printing? Probably not. So what types of inks are common in inkjet digital printing, and what printing technologies should you consider?”

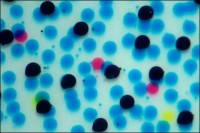

Hope goes on to note that there are “four main categories” of digital printing inks, including water-based, solvent-based, dye-sublimation and UV-curable, with all having two things “in common”: the two main components “are a colourant, either dye or pigment-based”, and all “use a carrier for the colourant, generally a liquid”. Again, in printhead technology there are two that “dominate”, specifically thermal inkjet and piezoelectric inkjet heads.

She points out that “in reality the press manufacturer will have chosen the inkjet printhead best suited to their preferred type of ink”, so when choosing a “suitable digital printer”, the buyer’s “main concern” is to “identify the types of substrates most likely to be printed”. This makes it “easier to decide which type of ink will be most suitable”, apart from the fact that “you need to take into account the expected operational life span of the printheads, the cost of maintenance, and/or the cost of replacement heads”.

As well as these elements, buyers need to consider the “actual cost of the ink, which you can generally base on the amount used per square metre for a specified density”. With “so many inks to choose” from, Hope then goes on to discuss the “two main carriers” of water or solvent-based inks, with water “generally seen as harmless and sustainable, while solvents are more problematic” because they contain volatile organic compounds (VOCs).

The solvents are also available in “many different flavours”, and VOCs “evaporate at low boiling points, so they evaporate quickly at room temperature”, with such vapours “mostly not healthy to inhale”. Machines using solvent-based inks “must have some sort of industrial air extraction mounted at or inside” the machine, and the attraction of using such inks is that they dry “very quickly”, are “durable” and have a “relatively large colour gamut”.