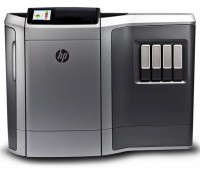

Half of the plastic in the new machine is “3D printed”, with the decision a “purely economic one”.

The Guardian reported on the MultiJet Fusion device, set to be launched before the end of the year, which includes 3D-printed parts for a “purely economic” reason. The site revealed that “half the custom parts” in the machine were 3D printed, with Head of 3D Printing Stephen Nigro telling The Guardian that the decision “helps the company highlight the quality of the printer’s output”.

He added that “for any given small plastic part […] if you’re making fewer than 55,000 pieces you’re actually better off printing than moulding”, adding that “the reason we’re doing it is not because we can, although that certainly would be one reason. It’s because we should: it actually makes economic sense for us to print those parts; we can actually save money”.

This decision was said to have been “made simpler by the comparatively limited quantities of 3D printers” that the OEM “expects to sell”, as the devices aren’t desktop 3D printers but aimed at the “prototyping and short-run manufacturing markets” for prices starting from $130,000 (€116,181) for the Jet Fusion 3D 3200 model. Nigro added that “approximately half the custom plastic parts in the machine are going to be 3D printed”, and that the OEM was “surprised to discover how much it could 3D print”.

He added that this was “because we were going through the development cycle and we had this goal of like, ‘OK, we want to have some of the parts in this printer be printed by the printer itself’, because we thought it would be cool to have the printer print itself. We honestly thought it would be probably five or six parts. And it wasn’t until we got pretty close to the introduction, we had handed over to our supply chain team who were looking at the economics and they came back and said ‘yeah, about half the parts, we’re going to print’”.

The Guardian noted that “the idea of a 3D printer that can 3D print a 3D printer is not new”, as in 2005 the RepRap open-source movement began, with the aim of “creating self-replicating machines”, though “in practice, the group creates and shares schematics for building and using a 3D printer that can print copies of itself – but has not yet succeeded”.