Future printing may be done using inkless paper and UV light.

Seeker reported that scientists have discovered a method of using nontoxic nanoparticles “to make rewriteable paper that can be printed and erased more than 80 times”. The article noted that worries about “deforestation, pollution and waste” from paper production concerns many, and that even though there is recycling, “a quarter of America’s landfill waste and a third of its municipal waste consists of paper”.

Yadong Yin, Chemistry Professor at the University of California, Riverside, said that the new technology “means you don;t have to spend a lot of money on the paper and the inks” as well as saving trees, where as before you had to cut 88 trees to make the same amount of paper that now takes one”. The rewriteable paper could be used for notepads, price tags and newspapers, said Yin, who worked with “other colleagues from Shandong University in China as well as Lawrence Berkeley National Laboratory”.

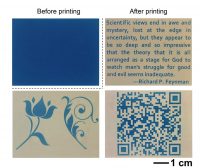

The printing was developed by taking conventional paper and coating it with a thin layer of nanoparticles that are responsive to light. In their experiment, the two types of nanoparticles were made of Prussian blue, which is “common, nontoxic blue pigment and titanium dioxide”, also non-toxic. These were mixed together and then applied to the paper, which turned blue.

The test was printed by using “a mask with the letters etched out and placed it on top of the coated paper”, which was then exposed to UV light, and the photons in the light were directed onto the titanium dioxide through the mask, whereby they released electrons, which then get “picked up by the Prussian blue nanoparticles”, and that makes them colourless.

The result of this is that some areas stayed blue and others became colourless, and this is what produced the text – also, after five days the print begins to fade away, but for speedier erasing the scientists found that “exposing the page to heat for 10 minutes” removed all the letters. The team have developed a “prototype printer” to use instead of the mask, and Yin said “because their version of a printer doesn’t require the moving components found in laser or inkjet printers already on the market, it would be much simpler to manufacture and maintain”.

Yin commented that “I would imagine this kind of laser printer will be much cheaper because it only involves light”. The team hopes to “develop a printer that’s able to print on a standard-size sheet of paper and then take the system to full colour”.